Firebricks for Sale

Refractory bricks are aluminosilicate fire refractory bricks with an AL2O3 content of 30% or more. Firebrick is a basic material for high-temperature technology and has a very close relationship with various industrial furnaces. Different kinds of refractory bricks also show different basic characteristics due to the differences in chemical mineral composition, struktur mikro, and production process.

PER refractory company produces high-quality refractory bricks including fire clay bricks, high alumina refractory fire bricks, silica fire bricks, magnesia fire bricks, mullite fire bricks, and insulation fire bricks, dll..

Sementara itu, if you are interested in our refractory firebrick products, or if you are planning to build a furnace or kiln, you can contact us! We will reply to you promptly with professional advice and a competitive price

Types Of Fire Bricks Products

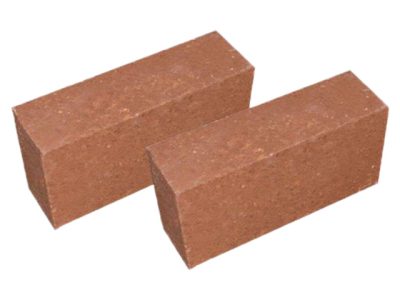

Fire Bricks

Our premium fire bricks are perfect for building fireplaces, ovens, and kilns. They are dense, tahan panas, and designed to withstand extreme temperatures.

Batu Bata Isolasi

Jaga agar tungku dan tungku pembakaran Anda tetap hemat energi dan waktu pemanasan berkurang dengan batu bata isolasi kami. Mereka menawarkan sifat isolasi termal yang sangat baik dan menjaga stabilitas termal bahkan pada suhu tinggi.

Batu Bata Magnesia

Batu bata berbahan dasar magnesia kami ideal untuk pelapis tungku bersuhu tinggi, tanur putar, dan insinerator. Mereka menawarkan ketahanan luar biasa terhadap panas tinggi, erosi kimia, dan kejutan termal.

Batu Bata Mullite

Batu bata Mullite menawarkan ketahanan guncangan termal yang sangat baik, ekspansi termal rendah, dan kekuatan besar pada suhu tinggi. Mereka sering digunakan dalam aplikasi isolasi listrik dan termal.

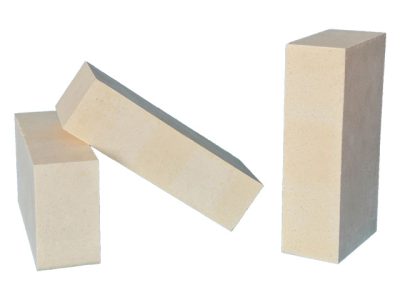

Bata Alumina Tinggi

Batu bata alumina tinggi kami terbuat dari bauksit berkualitas tinggi, dan sempurna untuk aplikasi suhu tinggi. Mereka dapat menahan suhu hingga 1780°C, tahan terhadap abrasi dan keausan, dan memiliki konduktivitas termal yang rendah.

Batu Bata Silika

Batu bata silika berkualitas tinggi kami sangat cocok untuk pelapis kiln, tungku, dan aplikasi suhu tinggi lainnya. Mereka sangat tahan lama, tahan terhadap korosi, dan dapat menahan suhu hingga 1600°C.

Batu Bata Chrome

Made from high-purity chromite ore, our chrome bricks are ideal for molten metal applications, such as in foundries and steel mills. They are highly abrasion-resistant, have low porosity, and offer excellent thermal stability.

Batu Bata AZS

Our AZS bricks are made from a unique blend of high-grade raw materials and advanced manufacturing processes that ensure unparalleled durability, resilience and resistance to thermal shock, erosion and chemical attack.

Batu Bata Tanah Liat

PER memproduksi batu bata tanah liat standar dan batu bata tanah liat khusus. Batu bata tanah liat yang kami produksi cocok untuk tempat pembakaran kaca, tungku keramik, tanur putar dan tanur industri lainnya. Suhu pengoperasian batu bata tanah liat standar adalah 1250℃-1350℃.

Batu Bata Ringan

Produsen batu bata tahan api PER menawarkan batu bata ringan standar atau batu bata tahan api khusus. Produk yang dihasilkan antara lain batu bata tanah liat ringan, batu bata silika ringan, batu bata mullite ringan, batu bata insulasi ringan, dll..

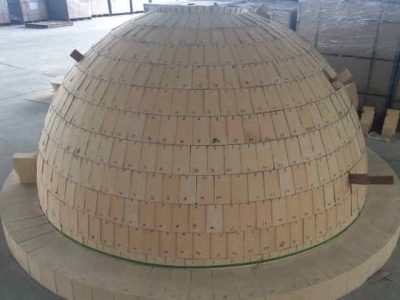

Bata Api Kiln

We offer a variety of alkaline refractory bricks, acid refractory bricks, and neutral refractory bricks. Juga, we can customize various kiln fire bricks on demand.

Bata Andalusit

Batu bata tahan api Andalusit PER memiliki konduktivitas termal rendah yang baik, ketahanan tinggi terhadap terak dan ketahanan mulur. Ini dapat digunakan dalam tanur sembur panas, menara ledakan panas, tanur tiup dan bagian penting lainnya.

How The Fire Bricks are Packed?

PER Refractory Manufacturing Company has many years of experience in exporting refractory bricks:

The general fireproof brick packaging is divided into two ways: wooden pallet or straw rope.

1. Wooden pallet packaging is generally 1m×1m in length and width, and the base is 15cm, so how are the refractory bricks placed in the wooden pallet?

Misalnya, the size of the standard brick is 230 * 114 * 65mm, four trips per layer vertical 15 of + horizontal 4 = 64.

According to the 3.4kg/block of clay bricks, it can be loaded with ten to twelve layers. Each pallet is packed according to the upper limit of 2.3 ton.

2. Straw rope packaging to standard brick as an example, generally 6 pieces packed together.

Refractory Brick Physical Chemical Function Reference

Firebrick’s basic quality requirements are alumina higher than 38% (biasanya 42-47%) as well as low iron and low alkali metal content, these should belong to its chemical properties.

But while you understand the physical properties like the specifications of fire bricks, don’t neglect to mention the physical and chemical properties of refractory bricks. Such properties include shaped refractory bricks, high alumina fire bricks for coke ovens, dll.. will have.

As fire-resistant bricks are a kind of ultra-fine silica powder material formed by the condensation of SiO2 and Si gaseous state that occurs during metallurgy of ferrosilicon alloy and industrial silicon with the rapid oxygenation in oxygen.

Foremost, the appearance of fireproof bricks is a gray and white powder, with refractories > 1600 ℃. Its capacity: 200~250kg/m3.

Kedua, the precision of fire-resistant bricks, fire resistant bricks in the precision of less than 1 micron accounted for more than 80%, per capita particle size in 0.1 ~ 0.3 microns, specific surface area: 20 ~ 28m2 / g. Its precision and specific surface area are about 80 ~ 10100 times that of steel, Dan 50 ~ 70 times that of fly ash. Its precision will be relatively higher.

Finally, the particle material state and mineral phase structure, fire-resistant bricks in the composition process, because of the process of phase change by the utility of the surface pull, constitutes a non-crystalline phase amorphous round spherical particles. And the surface layer is quite slippery, some are more than one round spherical particles stick in a case of cheerful aggregates.

It is a kind of volcanic ash object with a very, very large specific surface area and very, very high activity. The material mixed with fire bricks, a fine spherical body can play a lubricating effect.

Refractory fire-resistant bricks can be used as high-temperature construction materials and structural materials for building kilns. As well as a variety of heating equipment that undergoes various physical and chemical changes and mechanical effects at high temperatures. Such as clay bricks, batu bata alumina tinggi, silicon bricks, batu bata magnesium, silicon mullite bricks, dll..

High alumina bricks: High alumina refractory brick has more than 75% Al2O3 content and high refractories. It has a good ability to resist acid and alkali erosion. It is suitable for the location of the cement kiln firing zone.

Silicon carbide bricks: It has high-temperature resistance, ekspansi termal rendah, good wear resistance, dan ketahanan guncangan termal yang baik, and is suitable for kiln cooling belts and outlets.

Silica Mullite Bricks: The raw material is bauxite and silicon carbide, which is made by pressing and sintering. It is suitable for the transition zone with good thermal shock resistance, kekuatan tinggi, and good wear resistance.

Batu bata tanah liat: It is a weakly acidic refractory material. It has good thermal stability and is suitable for a hot air furnace chamber.

The Basic Properties Of Fire Bricks

PER Refractory has more than 20 years of experience in the production of refractory bricks and refractory castables. Our rich experience ensures that our products have very much refractory material price advantage and quality advantage:

1. Load Softening Temperature Of Fire Bricks

“Sifat tahan api” refers to the refractory products in the production of the application process that can be resistant to a high-temperature degree, and not be melted function. The fire brick hydraulic press can effectively reduce the cost and save material loss.

Especially in the finished product rate has great progress, not only can make a refractory factory improve production efficiency, but also can greatly save labor costs.

Itu “room temperature resistance Zhuang strength” is one of the main quality indicators for the use of non-fired heat resistant fire bricks products with indefinite refractory materials.

2. Refractory Brick Pressure Resistance Strength

Small porosity of fire rated products, indicating a good degree of denseness, and the quality of the brick is good.

Apparent porosity is the ratio of the volume of pores (yaitu, initiation of cavitation) to the total volume of fire-proof products within the atmosphere.

Firebrick products have two concepts of compressive strength.

One is called “room temperature compressive strength”, which is defined as the ultimate compressive stress strength in the indoor laboratory, according to the unit area of the specimen that can withstand without being destroyed.

The second is called “high-temperature compressive strength”, which is defined as the ultimate compressive stress that a refractory product specimen can withstand per unit cross-sectional area without being destroyed by firing to a specified high temperature. In refractory material, these two kinds of porosity are expressed in percentage.

3. Refractories Of Fire Refractory Bricks

The use of a four-column hydraulic system, pressing brick air force average, pressure, in the refractory industry than widely used.

Especially large refractories and special refractories production field, but also play an important role.

By changing the mold of the firebrick press, and material ratios, the production of a variety of special refractory materials becomes relatively easy.

Based on no increase in investment in equipment, refractory brick hydraulic presses can achieve a multi-purpose machine, a multi-purpose machine.

Another is called “true porosity”, itu adalah, the volume of all the pores in the refractory products (including the open and closed pores) to the total volume of the ratio.

“Normal temperature pressure strength” for general refractory products, is a measure of its impact on the furnace material, wear, and liquid slag flushing can resist one of the important indicators.

4. Porosity

“High-temperature load softening point” refers to the fire resistant bricks for sale products in the production process, not only to resist high temperature, and to resist the slag, a variety of metal or material solutions, or processing parts of the flushing corrosion, acid-resistant bricks and withstand the pressure of the structural parts of the furnace body. Have the above function of the extreme limit called “high-temperature load softening point”.

There are also a few professional kilns on the refractory products porosity requirements should not be too small, to have the function of resistance to rapid cold and heat.

About PER Refractories Group

PER perusahaan refraktori terletak di Kota Xinmi, Provinsi Henan, kampung halaman bahan tahan api di Cina. Perusahaan kami adalah perusahaan tahan api berbasis teknologi yang mengintegrasikan R&D, produksi, penjualan, dan layanan teknis. Sumber daya yang kaya dan kualitas yang sangat baik di wilayah ini memberikan kondisi unggul yang tak tertandingi untuk produksi bahan tahan api. Our main firebrick for sales are batu bata tanah liat tahan api, batu bata alumina tinggi, silica fire bricks, batu bata tahan api magnesium, batu bata mullite, insulation fire bricks, dan produk tahan suhu tinggi lainnya.

PER menganggap hal yang paling penting, kami percaya dalam menanggapi setiap produk dengan serius dan menerima setiap pelanggan dengan tulus. Untuk memberikan hasil yang cepat dan berkualitas tinggi bagi semua pelanggan kami. PER Refraktori akan menjadi produsen refraktori paling tepercaya dan mitra terpercaya Anda.

Perusahaan PER refraktori adalah basis produksi hijau, hemat energi, dan bahan tahan api baru yang ramah lingkungan. Perusahaan kami telah lulus ISO9001:2008 sertifikasi sistem mutu internasional dan GB/T24001-2004 / ISO14001:2004 sertifikasi sistem manajemen lingkungan, sertifikasi lembaga inspeksi kualitas perusahaan. Produk kami terjual dengan baik di lebih dari 20 negara di seluruh dunia. Mereka yang disukai produk tahan api untuk metalurgi, bukan besi, petrokimia, kaca, keramik, dan industri tahan api lainnya.