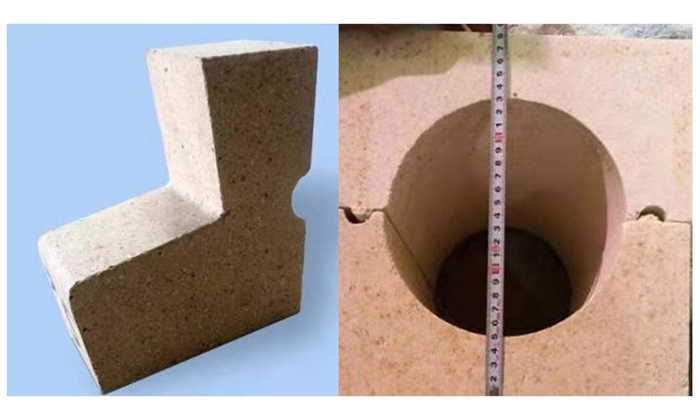

Andalusite brick

With high Al2O3 content and low impurity content, andalusite is an ideal high-grade refractory material. Andalusite refractory bricks have excellent low thermal conductivity, high resistance to slag corrosion, and creep resistance. Refractory alunite bricks have high thermal strength, low porosity, resistance to chipping and compression drop deformation, rintangan kejutan haba, and good refractoriness.

Andalusite bricks are mainly used in cooling walls, coke oven doors, hot blast stove lining, lattice, and so on in blast furnace, kimia, and ceramic industries. Refractory bricks can also be applied to the top of some metallurgical furnaces, the effect is better than silica bricks.

PER Refractories is a professional manufacturer of andalusite refractory bricks. We offer high-quality andalusite bricks and unfired andalusite batu bata. You can contact us in time to get the cheap andalusite bricks price.

Parameters of Standard Andalusite Bricks

| Index | GX-135 | GX-140 | GX-150 | |

| Al2O3 | (%) ≥ | 65 | 65 | 65 |

| Fe2O3 | (%)≤ | 1.5 | 15 | 1 |

| Bulk Density | (g/cm3) ≥ | 2.4 | 2.5 | 2.6 |

| Apparent Porosity | (%)≤ | 22 | 22 | 20 |

| Cold Crushing Strength | (Mpa) ≥ | 60 | 60 | 80 |

| 0.2Mpa Refractoriness Under Load | ℃≥ | 1520 | 1550 | 1600 |

| Refractoriness | ℃ ≥ | 1790 | 1790 | 1790 |

| (0.2Mpa, 20-50h, %)Creep rate | (%) | 0.2 | 1400℃ | 1400℃ |

| 0.2 | 0.2 | |||

| Rintangan Kejutan Terma (1000℃, water, quenching, cycle) | ℃ | 15 | 20 | 20 |

Advantages of PER's Andalusite Refractory Bricks:

1. High strength and wear resistance compared with traditional high alumina bricks.

2. Excellent thermal shock stability. Increase the service life of kiln lining and reduce the cost of refractory materials.

3. Excellent erosion resistance.

PER manufactured andalusite refractory bricks are suitable for blast furnaces, relau letupan panas, equalization furnaces, steel ladles, cement rotary kilns, ceramic tunnel kilns and glass kilns, dan industri lain.

The Difference Between Andalusite Mullite Bricks and Andalusite High Alumina Bricks

Andalusite High Alumina Brick

Andalusite high alumina bricks are made of andalusite as the main raw material, with bauxite added, after high-pressure molding, pengeringan, and firing at 1500℃.

Andalusite high alumina brick is characterized by high-temperature resistance, high softening temperature under load, and low creep rate at high temperatures, and not used in the volume of high-temperature volumetric stability, the use of the coefficient of thermal expansion is a small, low coefficient of thermal conductivity.

Andalusite Mullite Brick

Rutilated mullite brick is a kind of refractory brick made by adding different ratios of rutilated mullite and mullite to the composite.

This kind of fire brick has the advantages of good oxidation resistance, strong refractoriness, kekuatan mampatan yang tinggi, low specific gravity, good peeling resistance, high-temperature flexural strength, dan hayat perkhidmatan yang panjang.

Andalusite refractories 1830 ℃, chemical corrosion resistance, adding andalusite in high alumina refractory bricks, can make high alumina bricks with abrasion resistance and higher softening temperature under load, better resistance to rapid cold and heat performance. It can densify the brick joints at high temperatures and improve the overall compactness of high alumina brick masonry, thus improving the resistance to slag permeability.

Pendek kata, erythrite mullite and erythrite high alumina bricks have the same but also have a big difference, erythrite mullite bricks than erythrite high alumina bricks price is higher than erythrite high alumina bricks high-temperature erosion resistance, erythrite mullite bricks good flexibility, peel resistance is a little stronger.

Characteristics of Andalusite Bricks

Andalusite refractory bricks are made of andalusite as raw material, adding silica powder, mullite powder, and other powders.

These materials are in proportion to the addition of binder, and strict control of raw material particle size, grade, and its TiO2, R2O, and other impurities, selepas batching, pergaulan, acuan, pengeringan, dan penembakan suhu tinggi.

This can meet the modern blast furnace hot blast furnace different parts, different working environments use, to improve the service life of the blast furnace hot blast furnace is of great significance.

Andalusite refractory fire bricks will be transformed into mullite by heating, and after the transformation, it has a higher refractory performance.

Refractories can reach more than 1800 ℃, erythrite bricks have few impurities, and high-temperature strength decline is very small.

It is also resistant to rapid cold and heat, has high mechanical strength, strong thermal shock resistance, strong slag resistance, high load conversion point. And it has very high chemical stability (even insoluble in hydrofluoric acid) and very strong chemical corrosion resistance.

Industrial use of andalusite, mainly to take its role in high-temperature resistance. Andalusite at atmospheric pressure heated to 1350 ℃, after the beginning of the transformation into needle mullite. Mullite crystals are the only form of aluminosilicate that is stable at high temperatures.

Mengenai Syarikat PER Refractory

Syarikat PER Refraktori terletak di Bandar Xinmi, Wilayah Henan, kampung halaman bahan refraktori di China. Syarikat kami ialah perusahaan refraktori berasaskan teknologi yang menyepadukan R&D, pengeluaran, jualan, dan perkhidmatan teknikal. Sumber yang kaya dan kualiti yang sangat baik di wilayah itu menyediakan keadaan unggul yang tiada tandingan untuk pengeluaran bahan tahan api. Our main products are refractory clay bricks, bata tahan api alumina tinggi, bata silika refraktori, bata tahan api magnesium, batu bata mullite, bata penebat, dan produk tahan suhu tinggi yang lain.

PER considers the most important thing, we believe in taking every product seriously and receiving every customer sincerely. To provide fast and high-quality results for all our customers. PER Refractories will be your most trustworthy refractory manufacturer and reliable partner.

Syarikat PER refraktori adalah asas pengeluaran hijau, penjimatan tenaga, dan bahan refraktori baharu yang mesra alam. Syarikat kami telah lulus ISO9001:2008 pensijilan sistem kualiti antarabangsa dan GB/T24001-2004 / ISO14001:2004 pensijilan sistem pengurusan alam sekitar, pensijilan agensi pemeriksaan kualiti perusahaan. Produk kami dijual dengan baik dalam lebih daripada 20 negara di seluruh dunia. Mereka adalah produk refraktori pilihan untuk metalurgi, bukan ferus, petrokimia, kaca, seramik, dan industri refraktori lain.