Analysis Of The Causes Of Common Quality Problems In Tunnel Kiln Construction And Measures To Solve Them

The global building materials industry is developing rapidly, and the brick industry, new and technological transformation of the project using new technology, new technology, new equipment in an endless stream. Industry machinery supporting the preparation of raw materials, the system of extruders, automatic mechanical billet robot up and down system, and new ventilation equipment are more refreshing and delightful.

Many large brick enterprises using new equipment, and new technology tunnel kiln production line has been completed and put into production. And because most of the large-scale projects use advanced and reliable design and construction by large construction companies. Construction of strict quality management of the process flow, and thus the quality and target benefits are very good.

However, in the actual construction project, some enterprises will be completely avoidable for some reasons, construction of different degrees of quality problems, to the normal operation of the enterprise later to bring hidden danger, directly affecting the owner’s investment capacity goals and economic benefits.

The following is an overview of several construction parts of the project quality problems, cause analysis, and solution measures.

01

After the completion of the main part of a section of the foundation settlement problems.

Reason: a section of foundation backfill is deeper, the construction team did not put the width of the super-deep foundation under the replacement of the full width of the filling and layered too thick tamping is not enough to cause.

Measures: The construction team should pay attention to the super-deep backfill part to ensure the safety width and process quality, the owner should strengthen the management, and at the same time do a good job of site drainage measures.

02

The kiln centerline (both sides of the kiln wall) and the kiln car track axis are not consistent, the kiln long axis straightness deviation is greater than the specified requirements, which will affect the kiln to varying degrees of billet car operation.

Reason: only release the line with a latitude and longitude instrument, the construction of the line check, and review is not in place.

Measures: positioning with latitude and longitude, level fixed using ± zero origins, sub-processes on the foundation, rail beams, curved seal wall, picking brick, kiln wall, and other processes, check, check with the owner of the review (empty kiln car into the kiln with the check) and so on. This ensures that the kiln car the curved seal, and kiln wall clearance are consistent and smooth operation.

03

Kiln elevation control is not in place, there are parts of the kiln car with a ruler to check, the table side of the mouth from the pick brick mouth is 1.5 ~ 4cm, and kiln wall height error from the mouth to the mouth up to the maximum value of 3cm.

Reason: the construction team measurement and positioning check is not enough, the number of markers does not play a due role, and some of the refractory brick thickness is not standard.

Measures: the construction team should measure and check with a level meter, set up a standard number of poles to control the elevation and the number of layers in each construction section, and the refractory bricks with large errors should be selected for use in the kiln head or the kiln tail in the planning of a special construction section.

04

In the maintenance of the site found that some pick brick damage is serious and some have neighboring contraction joints near the wall damage problems.

Reason: After inspection, found that the pick brick length of 350mm, more than one damaged large part of the mortar fullness is poor (some of the construction projects also exist in the pick brick mortar joints are not full of the problem), mortar joints and mortar joints are not full of the damage will be accelerated in the production cycle. Hafenkou’s neighboring wall shrinkage gap is too close, and Hafenyi card brick wall extrusion pressure increases.

Measures: pick brick length should be > 390/400mm. Control of gray seams in the specification range and full, large error pick brick processing; ha wind mouth neighboring contraction joints to adjust the appropriate distance.

05

There are being repaired vaults (3.6m curved arch) the problem of subsidence deformation, and the same roasting section height varies, affecting the normal production period.

Reason: The poor strength of the arch seat beam cross-section is too small, less reinforcement and support wall spacing, the vault masonry mortar is not full, and the vault brick masonry wedges and grouting are not in place.

Measures: Strengthen the inspection during construction to ensure that the masonry mortar is full and wedge points wedged in place. Arch beam section concrete ratio, compactness, and reinforcement are in line with the requirements. In the middle section of the braced wall encryption, if there is no design supervision unit, these key process owners and construction team should strengthen the inspection, found that the unqualified part of the rework.

06

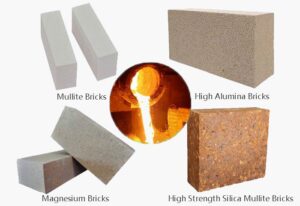

Refractory bricks under construction process inspection of refractory bricks test information is not complete. Broken bricks found within the black part of the pipe body weighing is not enough, there are specification size inconsistencies and other issues.

Reason: inspection is not in place, or the contract requirements are not clear enough, or low unit price.

Measures: refractory brick masonry is a key part of the kiln body, choose a reputable cost-effective supply manufacturer, the contract is clear and check (random sampling and inspection) in place, the refractory brick Al2O3 content, refractoriness, compressive strength, heavy, etc. should meet the requirements. The refractory bricks are classified and selected before masonry.

07

Problems with the Firehole construction: The Firehole construction line and Firehole arrangement are not straight, reducing the inspection holes (kiln ends are not enough layout), car line, and construction section (expansion joint position) line.

Reason: some construction teams think that the location of internal combustion fire eyes is almost not a big problem, in the construction of the kiln roof construction management is not in place.

Measures: pay attention to the construction of the kiln roof (especially the use of machine code billet project), each construction section of the position of the internal combustion fire eyes to control the kiln roof bricks, the number of rows of arrangement and gray seam size accurately in place and check.

08

Kiln car and the problem of the table: now the industry has several large-scale kiln car production enterprises, manufacturers can base on the design or program in the kiln body part size design supporting the standard kiln car, and supporting the applicable operating equipment, so that the owners of the construction unit do not have to worry about can be guaranteed to use.

But now a considerable part of owners because of the consideration of funds, own materials, personnel use, and other factors, the use of manual labor cost of homemade, some of the project kiln car and supporting the car table on the problem.

Some of the kiln cars before and after the closed unreasonable, some traction force point steel plate size is unreasonable, either too small or too thin, some shear support strength is not enough, some of the countertop insulation thickness of only 10cm can not reach the insulation effect so that the normal use of the future impact.

Reason: simply figure convenient and reduce the cost, or listen to the contractor’s advice, the investigation is not in place to consider.

Measures: to have set their construction or have been produced to rectify and strengthen: such as not doing track beams and sand sealing groove within the project appropriate to reduce the elevation to increase the insulation layer, kiln car table.

If not the formal design of the standard kiln and kiln car, kiln car countertops frame bricks (refractory bricks or custom processing block red bricks), need to be cut in the lower outer 50 ~ 80mm high 20 ~ 25mm after being embedded in the car, frame bricks from the edge of the upper part of the edge of the 100 ~ 120mm to cut the depth of 20mm plane. So that the billet under the bedding bricks is embedded solid not loose extrusion car edge wall, as far as possible to avoid collapsing billet and prolong the use of the kiln car table cycle.

It is reported that many manufacturers of kiln car table surfaces are not dealt with to increase maintenance costs and affect the turnover of kiln car use.

09

On the sanding pipe problem: some items are less, and should be set up in 5 to 6 pairs; some pipe diameter is too small, according to the kiln cross-section size can be selected in 120 to 160mm. Sanding pipe slope and pipe mouth from the bottom of the sand sealing groove size should be appropriate to achieve the effect of sand sealing in production use.

10

In some parts of the rebar tied molding more joint area is not staggered, joint length some long tens of centimeters, some short dozen centimeters. Should be strictly by the requirements of the construction specification binding of reinforcing steel.

11

Some masonry mixed cement mortar mixed with mortar king (can increase the mortar and ease mortar is not easy to precipitate), but most of them exceed the normal dosage, and some even exceed a few times, which will greatly reduce the strength of mortar masonry. Some concrete foundations, component beams, plates, and track beams’ self-mixed concrete strength is not enough. The owner and the construction team should strengthen the inspection and management, and the construction team should strictly use the matching ratio.

12

There are drying room openings without waterproof treatment so that condensate seeps into the kiln, and there are drying kiln roofs without insulation (or very thin), affecting the effect of heat preservation. The construction team should be strictly according to the design or use of the requirements of waterproofing and kiln roof insulation layer, and must not reduce the process links and lower quality standards.

13

Other suggestions

① Some manufacturers simply consider the cost of construction, and kiln length to be too short, to ensure that the roasting and drying cycle, can be considered comprehensively roasting kiln capacity car 30 to 33 car space, and drying kiln 20 to 23 car space. Do a good job of site drainage and slope safety.

② The construction team strictly puts the quality of the process, learning construction specifications and new technology construction methods, doing the construction of the process after passing the inspection of the next process, doing a good job checking the protection of construction materials and finished products, with the owners of the construction unit and the site representative of the inspection and supervision work.