Characteristics of Silica Bricks

Silica brick is the most common and important type of brick used in various types of glass kilns. Silica bricks are mainly used in the upper space of the glass kiln, such as the roof-swan, chest wall, end wall, small furnace, and heat storage chamber roof-swan.

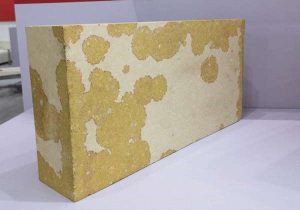

Production of silicon brick raw materials are mainly crystalline quartzite, adding a small amount of iron oxide, and calcium oxide as a mineralizing agent, to promote the scale of quartz as completely as possible and keep it in a stable temperature range of firing, SiO2 content of silica bricks to 93% as the lower limit, high-grade products for 96% ~ 98%.

Silicon bricks have high high-temperature structural strength, such as a high load softening point (1640 ~ 1700 ℃) and low creep rate [1550 ℃ – 50h – 0.2MPa – (6 ~ 7) × 10-5]. And in the absorption of a few alkali components in addition to very slight fusion, does not reduce the structural strength of the kiln roof.

The Main Disadvantage of Silica Bricks is The Low Thermal Shock Resistance

The firing of silica bricks is the key link in the whole silica brick production process, in which it is necessary to strive to maximize the completion of the phase transformation process, to form an ideal microstructure and have better performance.

According to the characteristics of quartz phase transformation, the following stages should be controlled in the firing:

(1) 500 ~ 700 ℃ stage is β-quartz transformed into the α-quartz range, with volume expansion of 0.82%. Calcium hydroxide decomposes and reacts with the surface of quartz particles in the solid phase to produce CS.

(2) 800 ~ 1000 ℃ range, under the action of the mineralizing agent, can generate a small amount of liquid phase, according to the electronic expansion meter measurement results, this stage has a slight contraction, this stage of firing is still relatively safe.

(3) 1250 ℃ above the temperature range, is the generation of the sub-stable quartz quartz stage, the quartz will have about 15% of the volume of the expansion, and the rate of heating to slow down as much as possible. But the amount of liquid phase generation will gradually increase and will be slightly balanced by the huge volume effect.

(4) 1350 ~ 1450 ℃ is a large number of scale quartz precipitation stage, from α-quartz into scale quartz will have 16.0% volume expansion, but the quartz can not be directly converted into scale quartz. But by the sub-stable quartz into scale quartz, the volume effect of this phase transition is not large.

However, it is important to control the rate of temperature increase at this stage because: The phase transition from quartz to stabilized quartz still occurs at this stage. This is because (i) the transformation of quartz to sub-stable quartz still occurs at this stage, and (ii) sufficient time should be given to ensure that the precipitation of the squadron is as complete as possible. Therefore, the firing and holding time of the stage above 1350°C is very important for the perfection of microstructure formation and obtaining the best high-temperature volume stability.

Silica brick for glass kilns is a silica refractory product mainly made of scale quartz used for the masonry of high-temperature parts of glass kilns. The higher the SiO₂ content in the silica raw material, the higher the refractoriness of the product. Widely used in glass kilns and kiln roofs, pool walls, and other parts.

Silica Bricks For Glass Kilns Should Have The Following Characteristics:

①High-temperature volume stability, will not cause changes in the furnace body due to temperature fluctuations.

② No pollution to the glass liquid.

③ Chemical erosion resistance.

④ Small bulk density.

Summarize

Silica brick belongs to acid refractory materials, with strong resistance to acidic slag or acidic melt erosion. However, it has poor resistance to alkaline erosion and is easily destroyed by the action of oxides such as Al2O3, K2O and Na2O. It has good resistance to oxides such as CaO, FeO, Fe2O3, etc.

Silicon bricks of more varieties, according to the use of coke ovens with silicon bricks, hot air furnaces with silicon bricks, electric furnaces with silicon bricks, glass kilns with silicon bricks, and so on. The complexity of the brick type is divided into standard brick, general type firebrick, shaped brick, and special brick, etc.